Piping Detail Engineering Service

Piping Detail Engineering Service Specification

- Consultancy

- End-to-End Piping Solutions

- Industry Served

- Oil & Gas, Petrochemical, Power, Water Treatment, Chemical

- Service Location

- Pan India

- Material Used

- Carbon Steel, Stainless Steel, Alloy Steel

- Project Management

- Comprehensive Engineering Documentation

- Mode Of Service

- Onsite & Offsite

- Quality Assurance

- Multiple Stage Review & Approvals

- Precision Level

- High

- Deliverables

- Complete Engineering Package

- Support

- Technical Query Resolution

- Design Standards Followed

- ASME, ANSI, API, IS Codes

- Service Type

- Piping Detail Engineering Service

- Documentation Provided

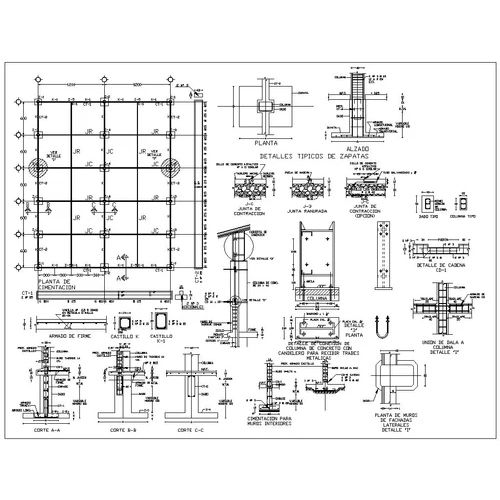

- Isometric Drawings, Piping Layouts, Bill of Material, Stress Analysis Reports

- Customization

- Available as per client requirement

- Duration Of Service

- Project Based

- Software Used

- AutoCAD, PDMS, CAESAR II, SmartPlant

- Safety Compliance

- Adheres to HSE Regulations

- Applicable Standards

- International Codes and Standards

About Piping Detail Engineering Service

Experience top-tier Piping Detail Engineering Service featuring remarkable precision and immaculate quality standards. Combining industry-leading software like AutoCAD, PDMS, CAESAR II, and SmartPlant, our service resplendently optimizes design for oil & gas, petrochemical, power, water treatment, and chemical sectors. Customization is readily available to meet unique client requirements, with end-to-end consultancy and technical support throughout. Our featured project management ensures multiple-stage reviews and approvals, delivering a complete engineering package that guarantees both substantial savings and strict safety compliance. Benefit from a comprehensive suite of documentation and international standards adherence. Available onsite and offsite throughout Pan India.

Piping Detail Engineering Service for Industrial Applications

The Piping Detail Engineering Service is suitable for large-scale plant environments such as refineries, power plants, water treatment facilities, and chemical units. With detailed usage in designing and optimizing piping systems, it supports plant operation, safety, and maintenance. This service is ideal for clients seeking tailored engineering solutions, regardless of facility size, ensuring efficient material usage and system integrity for prolonged operational reliability.

Service Sample Policy, Delivery, and Payment Terms

Clients can request piping service samples which are stock ready for immediate evaluation. Upon order confirmation, timely arrival and delivery of complete documentation and detailed drawings are ensured, in adherence with agreed project timelines. Flexible payment terms are available, structured for client convenience and project scope, facilitating a seamless procurement and service initiation process.

Piping Detail Engineering Service for Industrial Applications

The Piping Detail Engineering Service is suitable for large-scale plant environments such as refineries, power plants, water treatment facilities, and chemical units. With detailed usage in designing and optimizing piping systems, it supports plant operation, safety, and maintenance. This service is ideal for clients seeking tailored engineering solutions, regardless of facility size, ensuring efficient material usage and system integrity for prolonged operational reliability.

Service Sample Policy, Delivery, and Payment Terms

Clients can request piping service samples which are stock ready for immediate evaluation. Upon order confirmation, timely arrival and delivery of complete documentation and detailed drawings are ensured, in adherence with agreed project timelines. Flexible payment terms are available, structured for client convenience and project scope, facilitating a seamless procurement and service initiation process.

FAQ's of Piping Detail Engineering Service:

Q: How is the piping detail engineering process carried out for industrial plants?

A: Our process utilizes advanced tools like AutoCAD, PDMS, CAESAR II, and SmartPlant, starting from design conception to complete engineering package delivery, with multiple-stage quality reviews and approvals to ensure optimal results.Q: What materials are typically used in your piping detail engineering services?

A: We work with premium materials including carbon steel, stainless steel, and alloy steel, selected based on project specifications and client requirements to guarantee durability and system reliability.Q: When can clients expect the delivery of engineering documentation and reports?

A: Documentation such as isometric drawings, piping layouts, bills of material, and stress analysis reports are delivered as per the agreed project schedule, ensuring prompt arrival and availability for client review.Q: Where are your piping detail engineering services available?

A: Our services are accessible onsite and offsite across Pan India, covering major industrial hubs and remote project locations as required by clients.Q: What are the main benefits of using your piping detail engineering service?

A: Clients benefit from complete, customized engineering solutions, technical support, strict safety compliance, high-precision designs, and adherence to international codes and standards, leading to operational savings and enhanced plant performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free